By understanding these basic electronic components with symbols and their roles, you can start creating practical circuits.

Components with cold solder joints could are unsuccessful to ascertain electrical connections, resulting in practical failure.

Have you at any time wondered why a small electronic gadget can complete advanced jobs and supply strong performance? It’s all due to PCBA, which teams electronic components collectively with a circuit board to raise its performance and compactness.

Photolithography can be a course of action linked to manufacturing of ICs. A pure crystal of silicone, called the substrate, is positioned in a very chamber. A thin layer of silicone dioxide is deposited around the substrate, accompanied by another chemical layer, referred to as a resist.

A comprehensive final high quality Handle Check out is essential to make sure that all products fulfill high quality expectations, along with the inspection success ought to be documented.

g. insert '''' I'm Silly: r'$Delta$' ''' inside your code. The checker won't see $Delta$ is latex, it doesn't see r prevents escaping nearly anything, and it isn't going to see in any case this can be a remark enclosed in '''.

Excessive humidity can cause moisture absorption during the photoresist layer, resulting in it to soften and lose adhesion. Thus, it is essential to take care of temperature and humidity in just appropriate ranges in the course of PCB exposure to make sure the quality and adhesion from the photoresist layer.

These information have been processed via CAM, potentially together with producing payment, procedure optimization, and various essential changes. On condition that Every single maker has its possess engineering workflow, They could obtain these modifications unclear.

Utilized in healthcare designs where You will find ic chips a increased need to have for Electronic components accuracy and compliances to medical products. three. Army PCBA

The quality is a major problem. The faulty PCBAs can have an effect on the functionality and Procedure of electronic devices.

Together with these methods, we also advocate the Chinese suppliers which manage PCBA and assist with the correct components and effective procurements of the gadgets.

Following soldering, Visible inspection and AOI are performed to confirm the standard of solder joints and also to detect and rectify any soldering defects promptly.

PCBA tests is performed To guage the products’s final overall performance. Here are the widespread strategies useful for screening.

Solution: Choosing clean copper foil is critical. To lessen bubbles, increase lamination strain and tackle the boards gently. Often inspect and preserve the smoothness of the recent press rollers to forestall dents and contamination with the film.

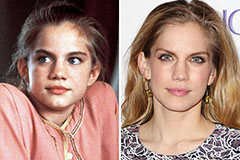

Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!